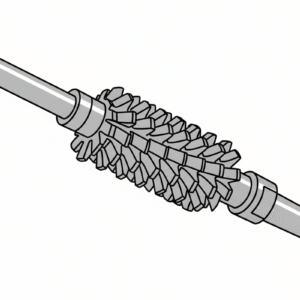

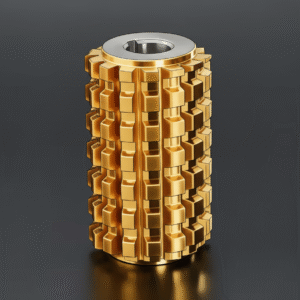

Gear Hobs

Gear hobs are essential, highly specialized cutting tools used in the manufacturing industry to generate the precise tooth profiles on gears, splines, and sprockets through a continuous cutting process known as hobbing. Operating on the principle of a rack and pinion, the hob acts as a rotating, helical cutter that removes material from a rotating workpiece, generating the final tooth form through relative motion. Hobs are classified based on the profile they cut—such as involute gear hobs for spur and helical gears, worm hobs for worm wheels, or spline hobs for shafts—and their construction (e.g., single-start vs. multi-start). The accuracy of the hob is critical, as it directly determines the precision, noise level, and lifespan of the manufactured gear, making gear hobs foundational to mechanical power transmission.

Reviews

There are no reviews yet.