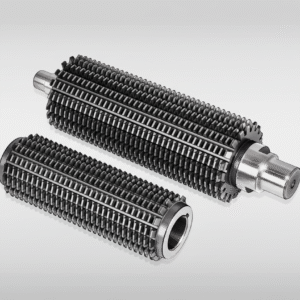

Involute Gear Hobs:

An involute gear hob is a specialized, cylindrical, helically gashed cutting tool used in the gear hobbing process to manufacture gear teeth with the common involute profile.

Key Characteristics:

-

Generating Principle: The hob’s cutting edges effectively function as a theoretical rack cutter (a straight-sided profile). As the hob and the gear blank rotate in a continuous, synchronized motion, this rack profile continuously generates the involute curve on the gear teeth.

-

Design: The cutting edges are wrapped spirally around the hob body, resembling a screw thread. Hobs are available in single-thread (for maximum accuracy, often used for finishing) or multi-thread (for high-speed production) designs.

-

Profile Forms: They come in various forms, including:

-

Finishing (for high precision)

-

Pre-shaving or Pre-grinding (to leave a uniform stock for later finishing)

-

Topping (which also machines the outside diameter of the gear blank)

-

-

Application: They are the primary tool for efficiently and accurately mass-producing standard spur and helical gears, as well as involute splines, used across industries like automotive, aerospace, and general machinery.

Reviews

There are no reviews yet.