Spline hobs are gear-cutting tools specifically designed to produce the grooves and teeth (splines) on a shaft or bore, enabling the transmission of torque. The two main types—Straight Side and Involute—are defined by the geometry of the tooth profile they generate, which fundamentally impacts the strength, alignment, and manufacturing complexity of the resulting spline connection.

Straight Side (Parallel Key) Spline Hobs

-

Profile: These hobs cut straight-sided, parallel teeth (often square or rectangular in cross-section) along the length of the shaft. This profile is simpler to manufacture.

-

Hob Design: They are generally designed for cutting parallel splines, sometimes featuring lugs for clearance or shoulder clearance to ensure straightness to the bottom of the cut.

-

Application & Use: Straight side splines are used where a simple, cost-effective design is required, typically relying on a tight major or minor diameter fit for centering. They are easier to manufacture, but they tend to have uneven load distribution and are not self-centering, making them prone to wear and vibration under high-torque or misaligned conditions. They are often found in older or lower-torque applications.

🌀 Involute Spline Hobs

-

Profile: These hobs generate a tooth profile based on the involute curve, similar to the profile of an involute gear, but usually with a shallower or “stub” tooth depth.

-

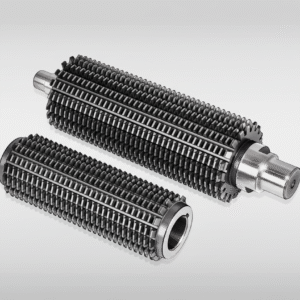

Hob Design: Involute spline hobs have straight-sided teeth, like a gear hob, and are manufactured in both single and multiple-thread designs for high-speed production. They adhere to industry standards like DIN 5480 and ANSI B92.1.

-

Application & Use: Involute splines are the dominant standard in modern power transmission (e.g., automotive transmissions, heavy-duty gearboxes) due to their superior performance. They offer uniform load distribution across all teeth, higher torque capacity, and possess self-centering characteristics when a side-fit design is used. While they require more complex and precise tooling, their advantages in durability and smooth operation outweigh the higher initial cost in critical applications.

Reviews

There are no reviews yet.